ENERGY

CASE STUDY

Case Study Template

Salmon producers Grieg Seafood Hjaltland had shipped smolts from mainland Scotland to their existing sites. A new, large-scale hatchery gave the company the capacity to produce in-house and on-site in Shetland. The new facility would cut transport costs, improve control on smolt quality and size, and reduce any risk from disease.

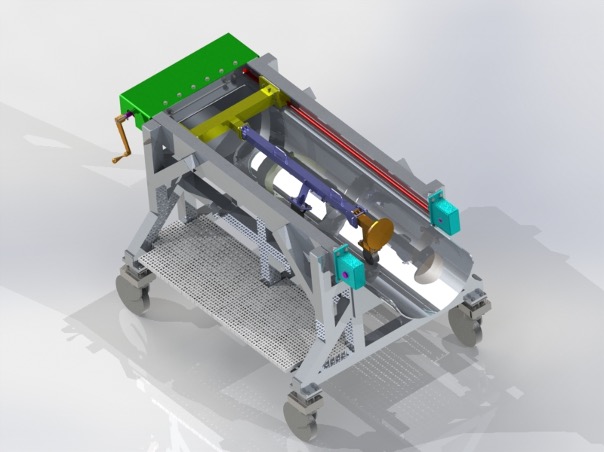

The contract included the complete redesign of the existing water intake and filtration system, the design, manufacture and construction of four buildings – to house egg-hatching units; the fry, parr, and smolt building; a new administration building; and a staff welfare building. All were carefully planned by the Ocean Kinetics design team based on their use, design and layout requirements.

Solution:

Ocean Kinetics’ work extended to designing and supplying pipework systems, as well as providing water circulation and ventilation throughout the facility.

Pipe systems were designed and installed, to allow the transportation of smolts to the well boat for delivery to the sea farms.

A 95-metre pontoon was designed and positioned to accommodate the company’s well boat. Mezzanine floors were erected to provide grading and vaccination areas. All works were designed in tandem with the recirculation systems for the hatchery to realise a 20-fold increase in growth rates from the hatchery that had previously occupied the site.

Ocean Kinetics drew heavily on the wealth of senior management experience gained from working in, and servicing, the sector to design and deliver this project to the client’s satisfaction.

KEY FACTS

OTHER CASE STUDIES

For assistance and support please contact:

Graeme Georgeson

graeme.georgeson@oceankinetics.com

T: 01595 697 908

Lewis Grant

lewis.grant@oceankinetics.com

T: 01595 697 913