MARINE WORKS

CASE STUDY

Port of Dover – install cathodic protection system

Project:

To design and install a cathodic protection system to the bearing piles which support Cruise Terminal 2 at the Port of Dover, Europe’s busiest ferry port.

Port 2 is the largest terminal at the Port of Dover. The vast size of the structure with limited access to it (3m wide gaps at each end and in the middle of the wave screen) resulted in a tricky working environment. Diving from the top of the quay was not possible.

The works were to be carried out during summer around the busy cruise ship movements, resulting in the additional challenge of not disrupting the daily coming and going of the ships.

Ocean Kinetics were required to install over 3,000 sacrificial anodes to the 380 bearing piles underneath the terminal and establish a method where the diver did not have to work under a quay at the end of a 150m umbilical.

Solution:

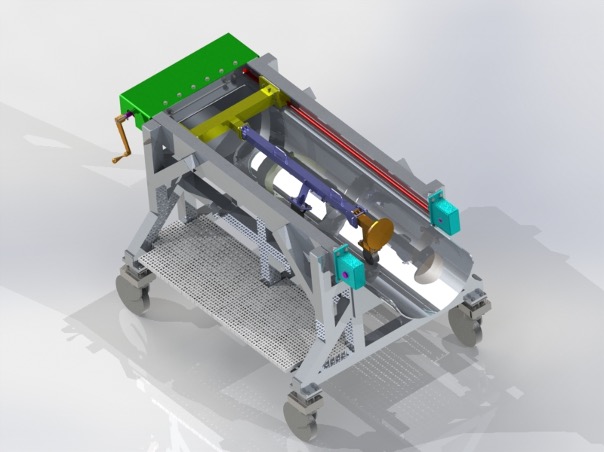

To overcome these challenges, Ocean Kinetics designed and built a 5m long aluminium workboat which was small enough to access all the piles under the quay, but also big enough to support diving operations from its deck.

Ocean Kinetics devised a way of mounting all the anodes on frames which would then be clamped to each pile in turn. Each frame was lowered over the edge of the quay and attached to a winch on a company boat. The anode frame was taken to the correct pile and hung in position ready for the divers to secure it.

All the components for the frames were fabricated in the Ocean Kinetics workshop and assembled on site by our welders.

The project was completed ahead of time with no disruption to shipping.

KEY FACTS

OTHER CASE STUDIES

For assistance and support please contact:

Roger Goudie

roger.goudie@oceankinetics.com

T: 0774 067 5464