PIPELINE PIG HANDLING EQUIPMENT

Ocean Kinetics produces a variety of pipeline pig handling equipment, for both offshore and onshore operations.

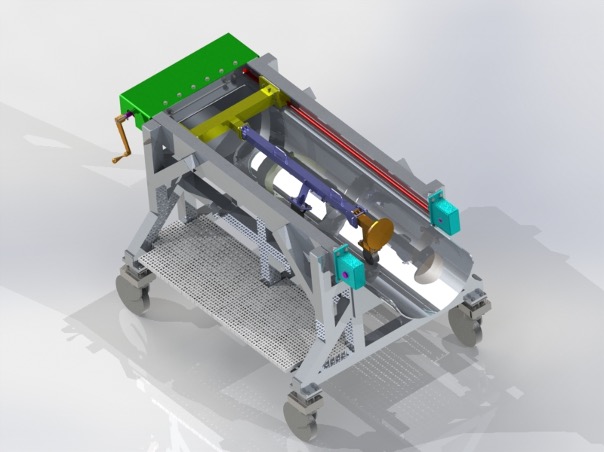

We offer custom designs to suit particular applications and also the Ocean Kinetics standard pipeline pig handling trolley. The features from our standard trolley can be readily incorporated into a custom product. The standard trolley can be manufactured to any length & diameter. Full CAD and 3D modelling is undertaken in-house. In line with the typical operating environment for this equipment, we aim to avoid power sources and use manual gear driven and manual hydraulic tooling where practicable.

For pipeline pig loading and retrieval, we offer a sectional push rod system which incorporates the Ocean Kinetics’ quick assembly coupling, to enable safe and easy operation. This coupling has a captive mechanism preventing the components becoming accidentally detached. The pushrods are sized for one person to assemble and manipulate them, using the incorporated handles, without any additional lifting equipment. The terminating pushrod can be supplied to fit against all joint types, from blind, to Yolk-Type connections, through to ANSI and compact flanges. The pushrod wheels can be supplied in a range of materials, polyurethane being commonly preferred.

The motive force for the pushrods is provided by geared handcrank; this has been carefully sized to provide quick travel with minimum of effort. All gears and travelling brackets are fully enclosed within the trolley, removing the risk of hand or finger entrapment. The Ocean Kinetics standard trolley includes the option for a single trolley to support multiple diameters of pipeline pig launcher/receiver. This is achieved by utilising lightweight inserts which align and secure centrally within the trolley bed.

The standard trolley includes oversized, braked, castor wheels that enable the trolleys to traverse grating and chequer plate. The castors incorporate threaded mounts to permit levelling and fine height adjustment. The large range of height adjustment required by some clients is achieved through the pinned legs within the trolley frame manual hydraulic jacks safely raise and lower the trolley bed; retaining pins then secure the final position. The jacks are stowed away to keep them secure and can be returned for inspection and maintenance without the need to return the full handling trolley.

In-lieu of pushrods, a winch and cable system is selected by some operators for pig recovery. Access decking has been incorporated into trolleys for some operators; this improves the ergonomics of working on a pipeline pig whilst it is stowed within the trolley. All trolleys are rated and tested for use as lifting apparatus and incorporate a selection of lifting and tie-down points.

Ocean Kinetics standard pig trolley features:

- To suit 36” diameter x 3m long pig/launch cassette, 2.5t SWL

- Manufactured from stainless steel, aluminium and carbon steel optional

- 10m of sectional push rods, Ocean Kinetics’ quick connectors

- Terminating rod incorporating mounting flange or interface flange to suit pipeline end feature

- Hand crank, reduction geared, fully enclosed pushrod drive mechanism – typical 1.5m stroke, readily adjusted to suit

- Fully height configurable with large travel and fine adjustment – nominally 700mm vertical

- Height adjustment by manual, long travel hydraulic jacks (supplied)

- Oversized, braked, castor wheels

- Lifting lugs and range of tie down points. Full trolly (including lifting lugs) independently load tested and certified

- Comprehensive guarding – no accidental access to drive gears and chains

- Optional inserts to suit a range of pigs and cassettes

- Manufactured with full traceability to ISO 3834-2 including EN 15614 WPSs and EN 9606 welder qualification (ASME IX option)

- Visually inspected and DPI tested (MPI for c/s) by PCN level 2 or equivalent

- Maker’s plate including SWL, UKCA/CE mark

- Operating and maintenance manual.

Learn about the pipeline pig cradle and the pig trolley we developed for Sullom Voe Terminal.